Performance Edition

The Performance Edition uses a more powerful, ultra-narrow linewidth laser to achieve the best results. It is the recommended version for users that are serious about Raman spectroscopy. Check this page to compare the Performance Edition with the Starter Edition.

All the files required to reproduce the Performance Edition are available here:

Download the files here: performance edition (rev2).

The current BOM sums to 3,063.04€ when using the custom LD&TEC driver. Some tooling might be necessary depending on what you have on hand in your lab.

Warning: The Performance Edition uses a Class 3b laser. Always wear laser safety goggles when operating the laser. Laser safety training may be mandatory in your institution to handle Class 3b laser. Owning Class 3b lasers may also be illegal in your country. Always check local regulations before attempting to reproduce the experiments reported on this website.

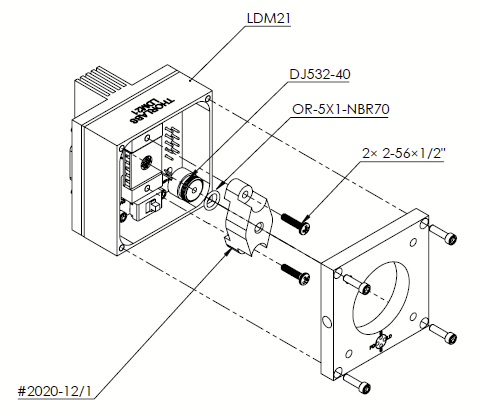

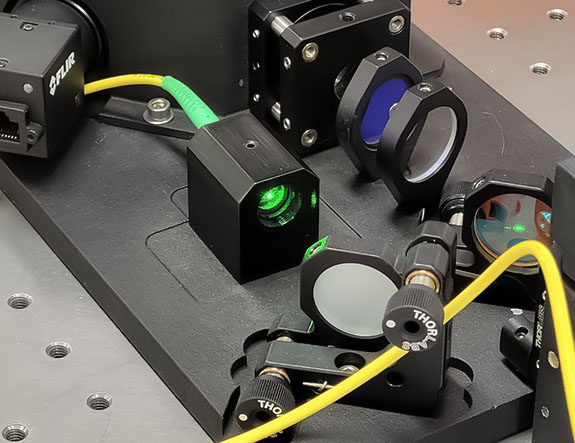

Begin by assembling the laser sub-assembly as shown here below:

Step 1/ Remove the front panel of the Thorlabs LDM21 and the sticky foam that is on the Peltier cooler. Degrease the Peltier using gentle acetone and cottons swabs. Let the acetone completely dry out before proceeding to the next steps.

Step 2/ Check that the LD switch is on “AG” (Anode Grounded) mode and install the DJ532-40 laser with the middle pin oriented top.

Warning: always use ESD mat when handling the laser diode. Failing to do so will damage your DJ532-40 permanently.

Step 3/ Install the o-ring in the groove of the #2020-12 (LD CLAMP) part. Set the clamp in place using two 2-56×1/2″ screws. If the screws are too long, use one or two washers. Do NOT overtighten the screws. The goal is to maintain the LD in contact with the TEC element without forcing on it.

Step 4/ Re-mount the front panel of the LDM21 and place the laser assembly on the base plate using two 8-32×3/8″ DIN912 screws.

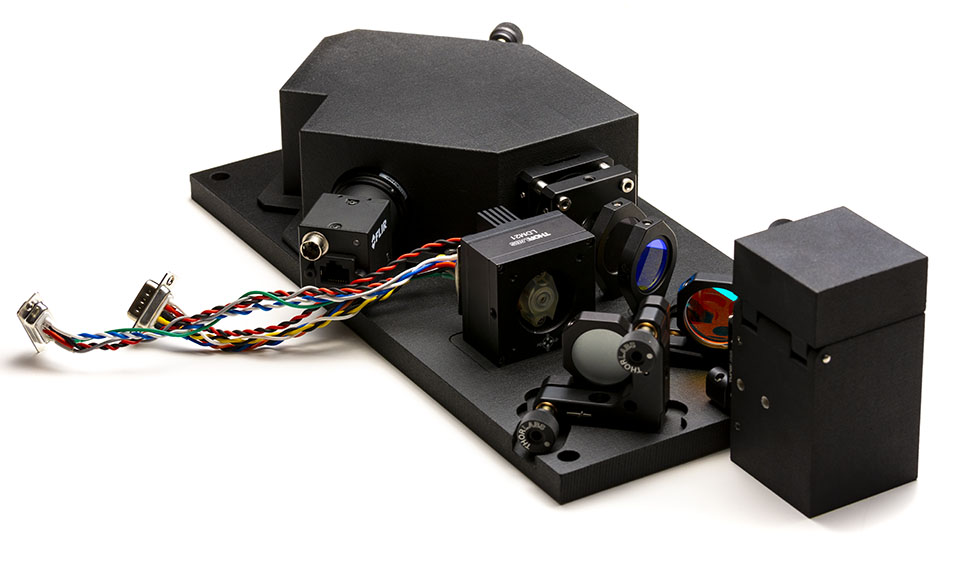

Step 5/ Assemble the rest of the spectrometer according to the instructions of the Starter Edition.

To power the laser, you will also need LD and TEC drivers. We offer two different solutions for that:

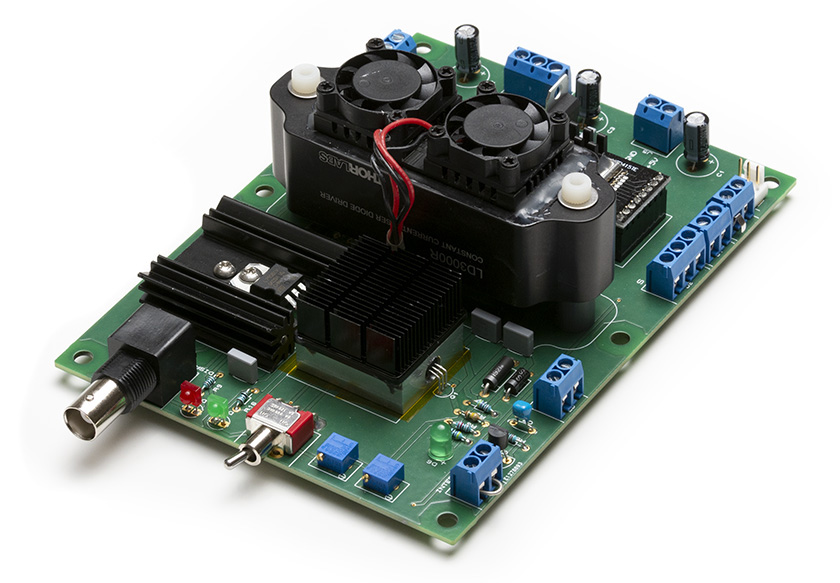

Custom LD & TEC Driver

The custom LD & TEC Driver is the perfect alternative for those who want to keep the price to a minimum! The circuit can be reproduced under 500€ and offers no compromise to more expensive drivers!

Lab-Grade LD & TEC Driver

If you are not feeling confident in assembling the custom LD & TEC Drivers yourself or already own LD & TEC Drivers in your lab, this solution is for you!

Fiber-Coupled Laser Add-on

For people preferring fiber-coupled lasers we propose a replacement solution to our 532 nm laser diode and drivers!

The holder is compatible with the Starter Edition and makes the Performance Edition really easy to build. This page explains how to modify the BOM of the Performance Edition and install the add-on.

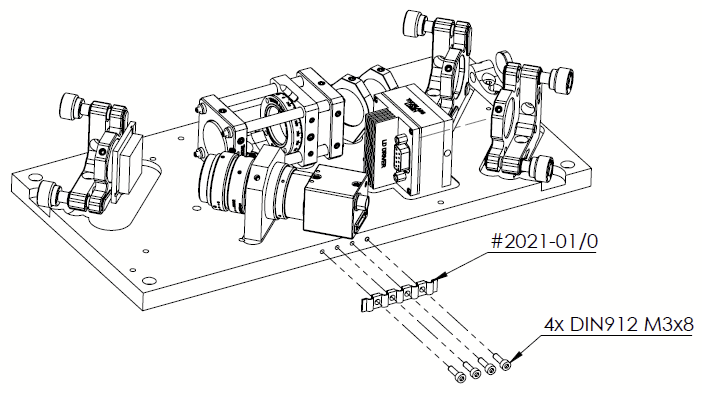

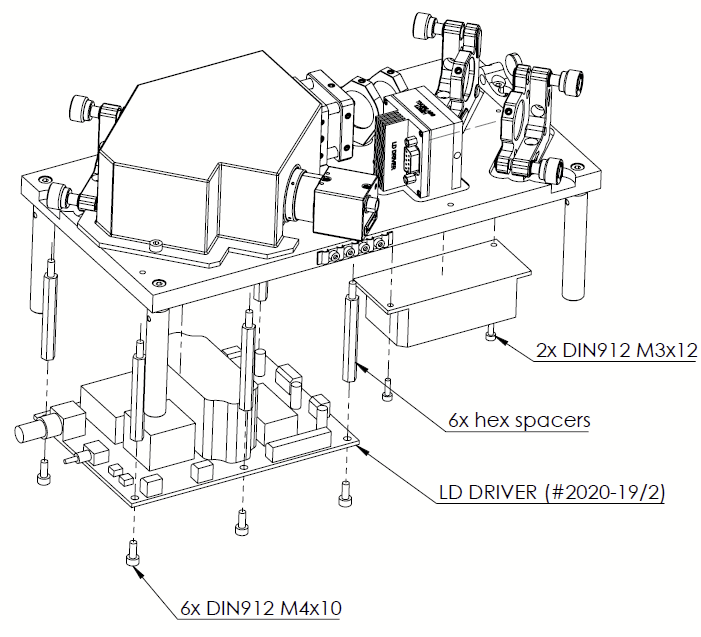

When using the custom LD&TEC driver, you can install it below the baseplate:

The cables can be secured to the baseplate using the provided flexure: